- Welcome to Tengjun New Materials (Thailand) Co., Ltd.!

- Return to Home | Add to Favorites | Contact Us

Mobile: 0622023113

WeChat: 15820932092

Email: yuyuancheng839@gmail.com

Thailand Address: Chonburi, Thailand

China Address: Building 4, No. 692, Dalingshan Section, Shida Road, Dalingshan Town, Dongguan City, Guangdong Province, China

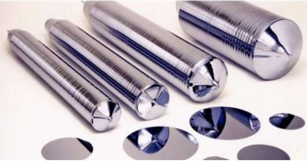

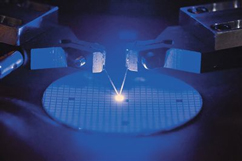

Silicon CMP Polishing Slurry

HPHE/SSPS-SH-2034 silicon material CMP polishing slurry is a high-end product manufactured by Guangdong Tengjun Chemical Technology Co., Ltd., widely used in the polishing process of large-size silicon wafers. In practical applications, this product has been highly praised by customers for its superior performance, including high concentration, high purity, low metal ion contamination, high rate stability, and good consistency. Since its market launch, the product has received positive feedback from numerous customers and has passed testing on multiple production lines in China, achieving excellent application results and reaching the performance level of imported products from the US and Japan.

II. Main FeaturesHPHE/SSPS-SH-2034 silicon material CMP slurry uses SiO2 hydrosol, synthesized in-house, as the abrasive. The synthesis process employs a new synthesis technology and automated production control, improving particle size uniformity and purity compared to traditional colloids, specifically designed for high-end products. The product formulation process utilizes a closed, automated preparation and synthesis method. All auxiliary reagents adhere to strict testing standards and are prepared and synthesized on-site, avoiding product quality issues caused by instability during raw material storage. In polishing, different formulation ratios can be optimized as needed to achieve the best results. Compared with similar products from the United States and Japan, this type of product has advantages such as high concentration, controllable abrasive particle size, low surface tension, easy cleaning of organic matter, metal ions and particles, high polishing rate, no non-homogeneous etching pits at high temperatures, and good polishing consistency.

III. Main ApplicationsPrimarily used for high-quality polishing of multi-diffused silicon wafers, and can also be used for polishing processes of raw germanium, silicon dioxide, and other materials.

IV. Basic Parameters| PH value | Specific gravity | Viscosity(mPa.s,25℃) | Particle size(nm) | SiO2% | Appearance |

| 10.0-12.5 | 1.265-1.300 | ≤5 | 120-140 | 38-42 | Milky white |

The recommended ratio of HPHE/SSPS-SH-2034 slurry to deionized water is 1:15-20, but the ratio can be changed according to actual process requirements.

1. Avoid direct exposure of the slurry during use to prevent contaminants from entering and causing scratches.

2. In winter, when the temperature is low (<5℃), the slurry should not be placed outdoors but stored in a temperature-controlled warehouse. Once gelation occurs, the slurry is unusable.

3. Clean pipelines and equipment promptly during slurry use to prevent slurry residue from forming in pipelines and containers, which can cause gelation and scratches on the wafer surface.

4. When recycling the slurry, a filter device should be added to the pipeline inlet to prevent gelation and repeated use, which can cause scratches on the wafer surface.

VII. Transportation and Storage1. The transportation and storage temperature is 5-40℃, with 25℃ being the optimal storage temperature. Store away from light to prevent deterioration of the polishing solution.

2. Shelf life is one year; it is recommended to use within six months.

3. Avoid contamination by metals and particles, and avoid contact with strong electrolytes.

Packaging Specifications25kg/drum, 250kg/drum, 1000kg/drum

-

About Tengjun

About Us Corporate Image Application Cases Leave a Message Contact Us -

Product Center

Silica Sol Series Polishing Fluids, Abrasive Fluids, and Polishing Pads Series Paint thinner, paint thinner, cleaning, and paint stripper series Organic Solvents Series View More + -

News

Company NewsIndustry NewsFrequently Asked Questions

0622023113(Please feel free to contact us for inquiries)

Pre-sales, sales, and after-sales online services