- Welcome to Tengjun New Materials (Thailand) Co., Ltd.!

- Return to Home | Add to Favorites | Contact Us

Mobile: 0622023113

WeChat: 15820932092

Email: yuyuancheng839@gmail.com

Thailand Address: Chonburi, Thailand

China Address: Building 4, No. 692, Dalingshan Section, Shida Road, Dalingshan Town, Dongguan City, Guangdong Province, China

GC and C Series (Silicon Carbide) POLIPLA Series

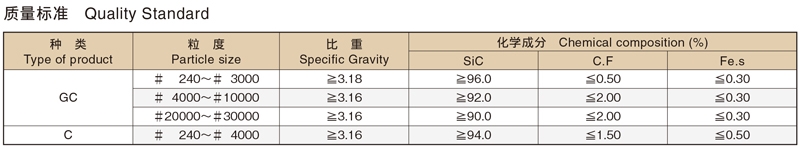

GC Series

GC is a green silicon carbide abrasive material with high SiC purity. The hexagonal α-type crystal, besides being second only to diamond in hardness, is also chemically very stable at room temperature. Therefore, it is not corroded by chemicals and can generate sharp grinding edges through self-crushing, thus exhibiting excellent grinding capabilities. GC is widely used not only as an abrasive material for fine polishing of crystal and ferrite, or for wire saws cutting Si crystal rods, but also for machining from other superhard metals or cutting tools to soft metals such as brass and copper alloys, and resins. It is also the most suitable material for precision grinding stones used in finishing. Furthermore, due to its semiconductor properties and good thermal conductivity, it can withstand high temperatures and is therefore also used as a material for heat sinks (heat dissipation components).

C Series

C is a black silicon carbide abrasive material, also commonly known as diamond abrasive. Similar to GC, it is composed of α-type silicon carbide crystals obtained by thermally reacting silica with coke in an electric resistance furnace at temperatures exceeding 2000°C. While its purity and hardness are slightly lower than GC, its toughness is excellent. Products manufactured using our unique method possess stable cutting edges and a particle size distribution ideally suited for abrasive processing, enabling excellent surface finishes. Besides being used in abrasive paper and precision grinding stones for ultra-precision machining, C is also ideal for fine polishing of cast iron, brass, copper, aluminum, stone, and photomask glass. Furthermore, it is suitable for precision grinding and cutting of semiconductor crystals.

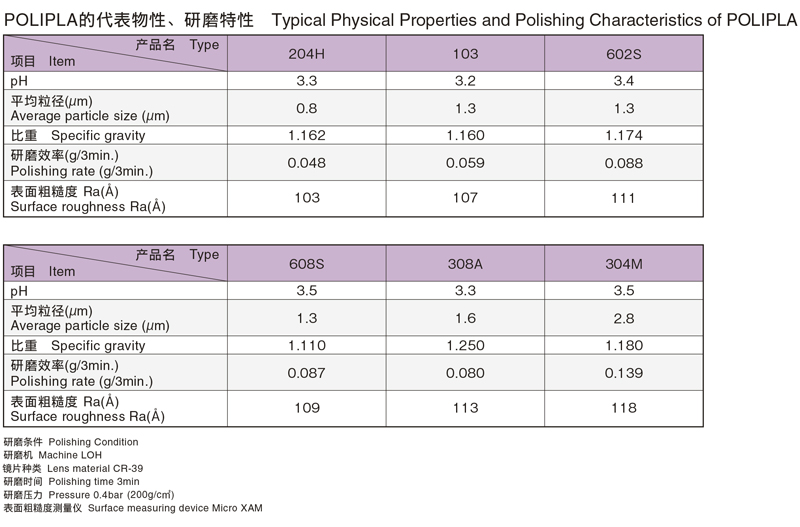

POLIPLA Series

POLIPLA is a composite polishing slurry with a pH value between 3.0 and 4.0, making it ideal for polishing various synthetic resin lenses. Its appropriate combination of abrasive grit size and hardness significantly improves efficiency while ensuring a highly polished lens surface.

POLIPLA is also widely used for the initial polishing of high-hardness alloy resin or plastic mirror molds (followed by fine polishing with COMPOL), as well as for polishing watch dials and other metals, resins, and plastics.

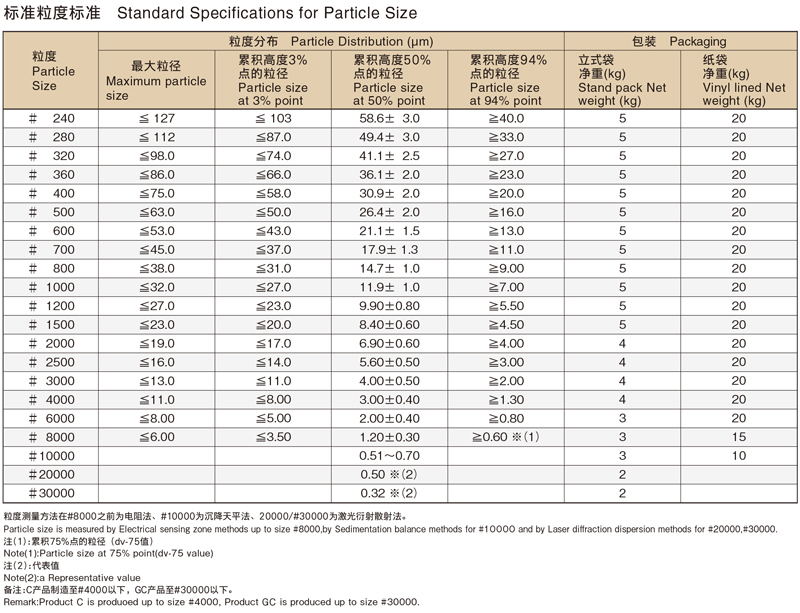

II. Standard Grit Size Standard

-

About Tengjun

About Us Corporate Image Application Cases Leave a Message Contact Us -

Product Center

Silica Sol Series Polishing Fluids, Abrasive Fluids, and Polishing Pads Series Paint thinner, paint thinner, cleaning, and paint stripper series Organic Solvents Series View More + -

News

Company NewsIndustry NewsFrequently Asked Questions

0622023113(Please feel free to contact us for inquiries)

Pre-sales, sales, and after-sales online services