- Welcome to Tengjun New Materials (Thailand) Co., Ltd.!

- Return to Home | Add to Favorites | Contact Us

Mobile: 0622023113

WeChat: 15820932092

Email: yuyuancheng839@gmail.com

Thailand Address: Chonburi, Thailand

China Address: Building 4, No. 692, Dalingshan Section, Shida Road, Dalingshan Town, Dongguan City, Guangdong Province, China

WA, PWA, and A Series (Alumina)

A Series

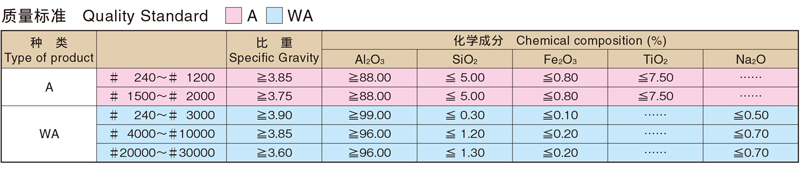

A is the most well-known abrasive material, also commonly known as synthetic corundum. It consists of corundum crystals with an Al2O3 purity of over 90%, obtained by melting bauxite in an electric furnace at a high temperature of 2000°C. A key characteristic is the addition of a certain percentage of alumina to improve its toughness (resistance to breakage) as abrasive grains. As a result, it possesses the highest toughness among abrasive powders, and with a precisely adjusted particle size distribution, it achieves high grinding efficiency and a scratch-free grinding surface, maintaining stable grinding performance. A is well-suited for use as a material for precision grinding stones and abrasive cloths for ultra-precision machining. It is also the most suitable abrasive powder for fine polishing of various glass materials, such as cathode ray tubes, and soft metals.

WA

WA is a white alumina abrasive material, a typical precision machining powder applicable to a wide range of applications. The manufacturing method involves micro-pulverizing and granulating molten alumina. The resulting alumina is high-purity alumina with an Al2O3 purity of 96.0% or higher, composed of α-type corundum crystals. It possesses a hardness second only to silicon carbide, maintains a sharp particle size distribution and stable particle shape, and allows for high-level surface finishing. WA exhibits excellent performance as a precision abrasive stone material for ultra-precision machining, abrasive cloth material for ultra-precision machining, and abrasive belt material for ultra-precision surface finishing. Furthermore, it is suitable for fine polishing of metals, glass, crystal, and semiconductor crystals lacking tensile strength. It is chemically inert, can withstand high temperatures, and has extremely high insulation properties. Moreover, due to its purity being maintained through chemical treatment, it exhibits excellent reaction stability with organic matter, and is therefore widely used in high-grade fillers (filler materials) for epoxy resin insulators, etc.

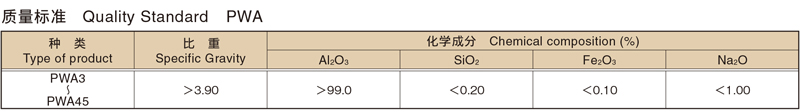

PWA

PWA is a high-quality alumina abrasive material composed of plate-like Al2O3 crystals with an Al2O3 purity of 99.0% or higher. It exhibits excellent heat resistance and is chemically inert, resisting corrosion by acids or alkalis. Furthermore, its stable particle size distribution allows for precise grinding surfaces and excellent grinding efficiency.

PWA is a versatile and widely applicable abrasive material. Besides being suitable for coarse polishing of silicon, optical materials, crystal, stainless steel, and other metals, it is also ideally suited for use as a filler in coatings, abrasive paper materials, and in composites with metals and synthetic resins.

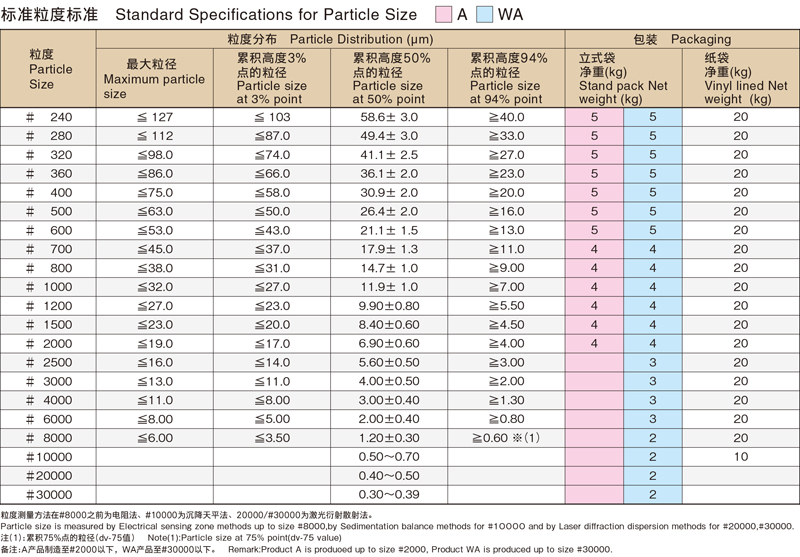

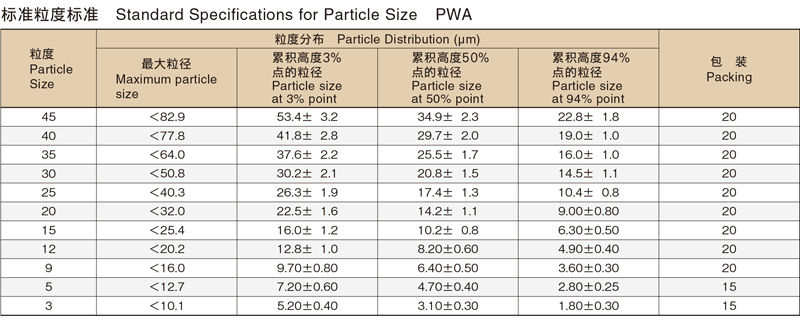

II. Standard Particle Size Standards

-

About Tengjun

About Us Corporate Image Application Cases Leave a Message Contact Us -

Product Center

Silica Sol Series Polishing Fluids, Abrasive Fluids, and Polishing Pads Series Paint thinner, paint thinner, cleaning, and paint stripper series Organic Solvents Series View More + -

News

Company NewsIndustry NewsFrequently Asked Questions

0622023113(Please feel free to contact us for inquiries)

Pre-sales, sales, and after-sales online services